When many people want something done in stainless steel, they think it will arrive to them standard as a brushed finish. Many household items like stainless appliances, faucets and taps are commonly provided as brushed nickel, which gives this impression. To get that finish stainless steel must go through a polishing process. At Emtek, we offer mechanical polishing capabilities on our stainless-steel parts when needed.

The polishing process is not unlike sanding a wood project down to get a smooth finish. The pieces run through a conveyor system with a belt that grinds away the metal to create a smoother and smoother finish. The first step is starting with a rough, heavy grit belt (60 or 80 grit) to remove the thick outer scaling that is on mill finish (also known as #1 finish) 304 and 316 stainless steel.

Hot rolled stainless steel showing a mill finish.

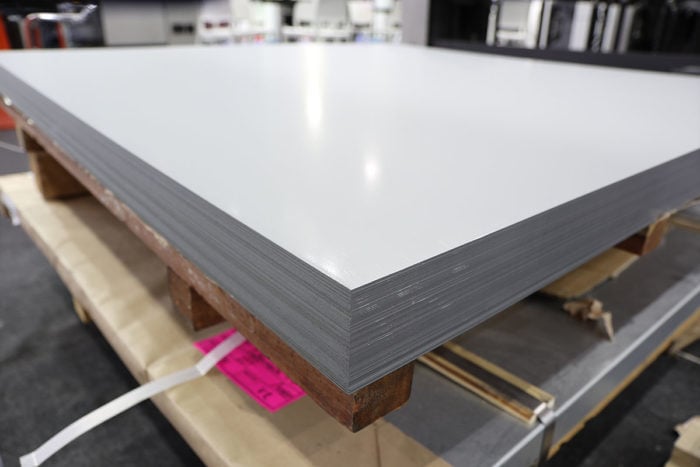

At times, this step is unnecessary, and that would be when the material is produced in a cold rolled method. This creates what is commonly known as a 2B finish.

A stack of smooth 2B finish stainless steel sheet

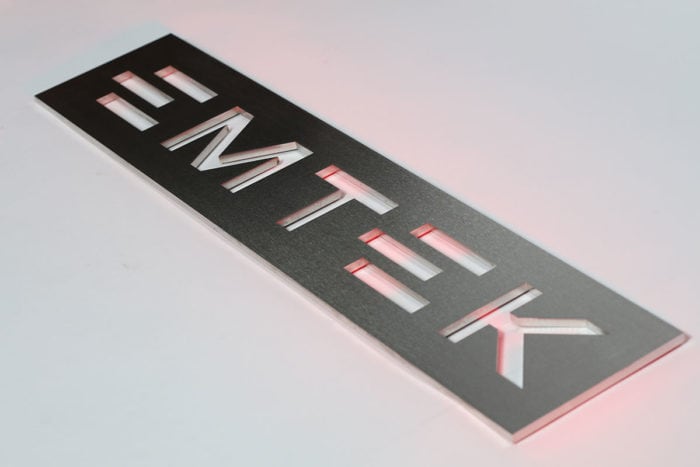

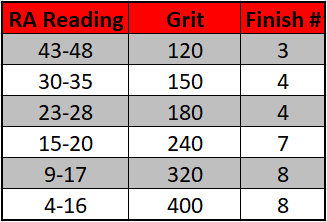

After this we progressively increase the grit of the belts up to 180 grit, which is known industry wide as a #4 finish. This is the most common finish for a “brushed finish” look. It is commonly used in food and kitchen environments as well as hospital and other sanitary applications. It can also be measured by what is known as an RA Meter. #4 finish ranges anywhere from 23-35 RA. (The higher the number, the rougher it is).

A laser cut logo with a #4 (180 grit) polished face.

To go much higher than a #4 finish a wet application needs to be applied. This will then need to be moved to polishing with abrasive compounds etc to create an extreme polished mirror finish look.

For more information about Emtek’s internal polishing capabilities please check out our polishing page.