Esthetic to Sanitary, we will take your project there.

Abrasive plate polishing completes your project or raw materials more efficiently and consistent than manual finishing.

Abrasive plate polishing completes your project or raw materials more efficiently and consistent than manual finishing.

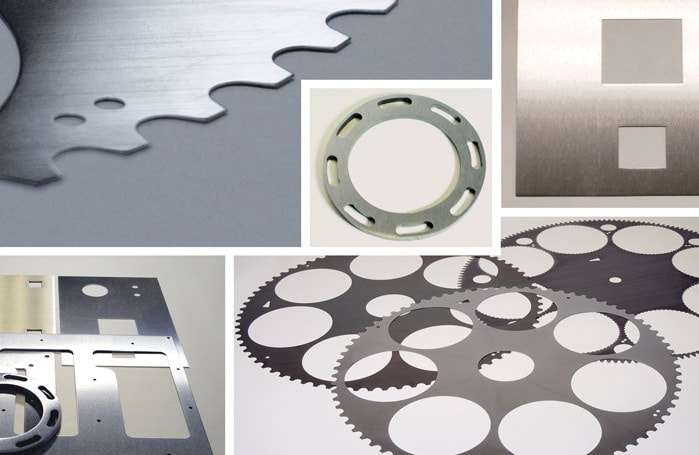

Giving your parts the final touch, stainless steel plate polishing can take your components from good to great, both esthetically and sanitarily.

Polishing is often used to enhance the appearance of an item, prevent contamination of components, remove oxidation, create a reflective surface, or prevent corrosion. Polishing stainless steel can also increase the sanitary benefits of it.

The condition of the material at hand determines what type of abrasive will be applied. The first stage, if the material is unfinished, starts with a rough abrasive (60 or 80 grit) and each subsequent stage uses a finer abrasive, such as 120, 180, 240, 320, 400 and higher grit abrasives, until the desired finish is achieved. The rough (i.e. large grit) passes remove imperfections within the metal surface like pits, nicks, lines and scratches. The finer abrasives leave progressively finer lines that are not visible to the naked eye

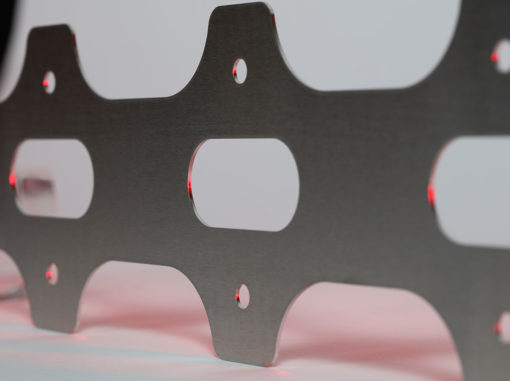

Emtek offers mechanical & manual metal polishing processes allowing us to completely satisfy your needs. Manual polishing for products with complex geometry requiring detailed craftsmanship to polishing for large orders that need an easy to replicate decorative finish.

Plate Polishing Processing Capabilities: 34″ x 144″, Max 4″ thk