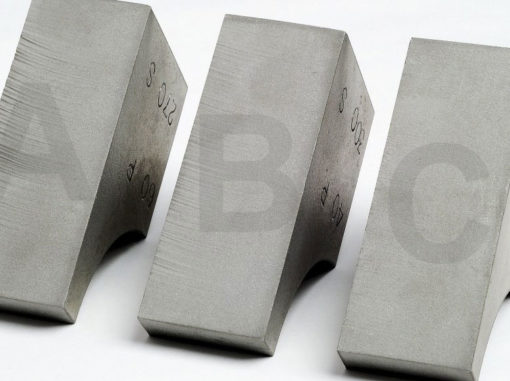

Heavy Material. Tight Tolerances.

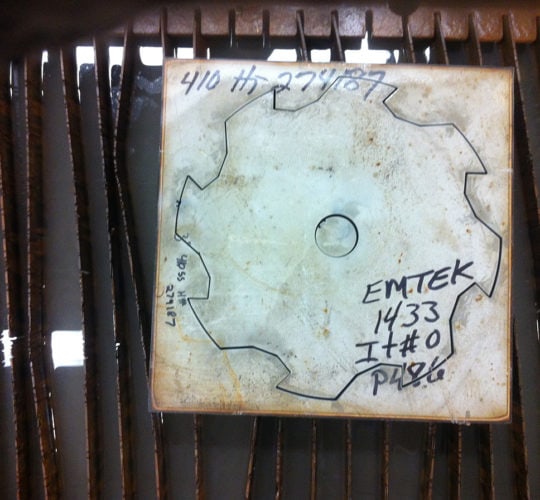

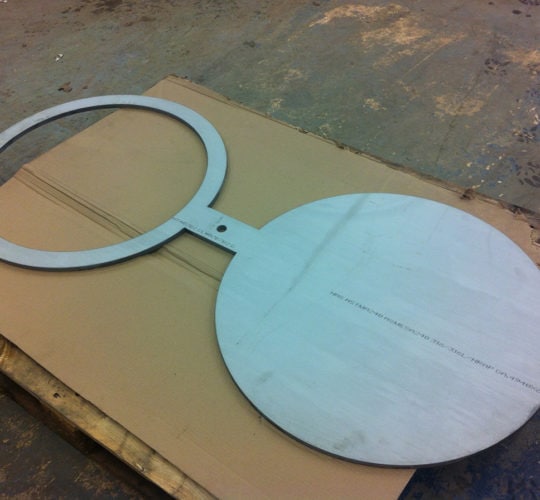

Emtek’s state of the art dynamic head and 87,000 PSI processing capability creates high precision erosion to allow for smooth finishes and tight tolerances on even the thickest and hardest of materials.

Waterjet cutting is often considered a substitute or primary process for precision machining in the manufacturing process. It offers many benefits that traditional machining methods can not achieve. This is especially true when the materials being cut are sensitive to the introduction of heat from contact associated with other methods. Waterjet cutting is generally popular in industries including, but not limited to water treatment, aerospace, mining, nuclear, oil and gas and architectural applications requiring a high degree of aesthetic edge quality.

Employing Flow Waterjet’s patented Dynamic Head processing mode Emtek can ensure that not only are your parts cut within dimensional tolerance but also a produced with a minimal amount of taper compared to non-dynamic waterjet processing offered by the competition.